DEWA-F for producing organo-mineral fertilizers

- From Peat (turf)

- From Sapropel

- From Leonardite

- From Bird droppings or manure

- With NPK-additives or without

DEWA-F is a multifunctional complex for producng organo-mineral fertilizers in a form of gel. Fertilizers can be produced from peat (turf), biohumus, sapropel, etc. Fertilizers produced in DEWA-F have higher content of humic acids.

Horse or poultry manure, processed in DEWA-F, is almost completely disinfected and is also suitable for use as fertilizers. Additional desinfection (decontamination) can be made by a static reactor.

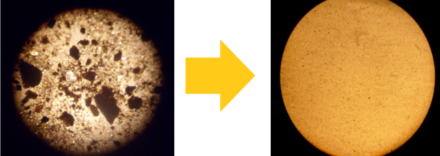

DEWA-F make additional micronization of raw material up to 50…110 mkm. If raw is not prepared we recommend to use our Wet Milling Machine (WMM-2)

Benefits of DEWA-F

The undeniable advantages of the two-stage processing of DEWA-F are:

- No need for manual screening of raw materials for branches, stones, and sand

- Low energy consumption – 10-14 kWh per m3 compared to rotary type machines

- Low cost of milling parts per 1 m3 of obtained organic fertilizers – about 5 times lower than in rotary type machines

- Ability to obtain organic fertilizers with a high solid phase content – up to 23-25%

- Ability to add NPK supplements at any stage of organic fertilizer preparation, depending on the recipe adopted by the Customer

- Easy operation and the possibility of almost complete automation.

DEWA-F complex is a reliable and efficient solution for producing high-quality organic fertilizers. With our two-stage processing system, you can save time and energy while ensuring a consistent and high-quality product. Our system eliminates the need for manual screening of raw materials, reducing labor costs and ensuring a more efficient process. Our low energy consumption and low cost of grinding elements also make our system an economical choice. With the ability to add NPK supplements at any stage of organic fertilizer preparation, our system provides flexibility to meet your specific needs. And with its user-friendly design, the DEVA-F complex is easy to operate and can be almost completely automated. Choose DEVA-F for a cost-effective and efficient solution to your organic fertilizer needs.

OMF PRODUCTION STAGES

Stage 1. Preparing of Raw Materials

Raw material for organo-mineral fertilizers (OMF) normally has solid includes sand, stones, wood chips and others, which do not allow to process it further.

Preliminary sieving typically is not very effective for and does not separate tiny stones and sand from the peat, sapropel or brown coal which are used as raw materials.

The best solution for preliminary preparation of raw material is a Wet Milling Machine which makes several function:

- wet milling of peat (turf) till 200…300 micron

- crushing of stones, sand and other includes till 100…200 micron or lower

- production of homogeneous (uniform)slurry with a consistency similar to thick yogurt.

Stage 2. Processing

Slurry, produced in a Stage 1 then processed in RIA or static reactors. If Stage 1 is eliminated then peat is milled and homogenized in a DEWA-F based on RIA.

That allows to produce a final product with a grainsize D90 below 120 micron.

For experimental and small-scale productions, we recommend using DEWA-F.MINI, where the first and second stages are made by rotary machines RIA for both grinding and cavitation processing.

DEWA-F.MINI is a compact and efficient system that uses RIA rotary machines for both grinding and cavitation processing, providing a cost-effective solution for smaller production operations. With its compact size and simple design, DEWA-F.MINI can be easily integrated into existing production lines, allowing for seamless operation and increased productivity. The use of RIA rotary machines ensures reliable and consistent performance, while also minimizing energy consumption and maintenance costs. Whether you’re a small-scale producer or wish to make experimental production, DEWA-F.MINI is the perfect solution for your organic fertilizer production needs.

Характеристики продукта (ОМУ)

| Modification | Characteristics | Typical Configuration |

| DEWA-F-150 | Capacity: 2…3 m3 of product per shift Manual load of raw material. Raw must be pre-crushed below 2mm, stones and other solids must be separated Max energy consumprion: 8 kW |

|

| DEWA-F-200 | Capacity: 5…10 m3 of product per shift Manual load or Conveyor of raw material. Raw must be pre-crushed below 2mm, stones and other solids must be separated Max energy consumprion: 15 kW |

|

| DEWA-F-250 | Capacity: 15…25 m3 of product per shift Conveyot load of raw material. Raw must be pre-crushed below 2mm, stones and other solids must be separated Max energy consumprion: 24 kW |

|

Final Product Characteristics

- Gel (turfgel, peatgel) with yogurt consistence, dark brown color, light peat odor

- Not separated for a long time, at least 4…6 months

- Doesn’t mould during a storage

- Typical particles grainsize: D90 below 118 mkm

- Dry matter content up to 18%

- Humic Acids content: up to 20 g per liter. Can be increased up to 30 g per liter with DEWA-S complex

Модельный ряд и Характеристики ДЭВА-Ф

Комплексы подготовки органо-минеральных удобрений ДЭВА-Ф доступны в нескольких модификациях.

Для малой производительности рекомендуем использование ДЭВА-Ф.МИНИ (ранее ДЭВА-Ф-150) на базе РИА-150М. Подача сырья осуществляется вручную, сырьё желательно заранее готовить путём очистки от веток и мелких камней. Данный комплекс подходит для небольших предприятий, работающих нерегулярно. При этом ДЭВА-Ф.МИНИ обладает полным функционалом для получения ОУ и ОМУ с различными добавками.

Для производства промышленного уровня более 10 м3 в смену/сутки и работе от 10 суток в месяц, рекомендуется использовать ДЭВА-Ф.ПРО на базе ГУУМП + ДЭВА-С. В данном комплексе используется двухстадийная подготовка балластных органических удобрений:

- Стадия 1. ГУУМП обеспечивает эффективное измельчение исходного сырья без необходимости просеивания от твёрдых включений (камней, песка).

- Стадия 2. ДЭВА-С обеспечивает увеличение выхода гуминовых кислот благодаря интенсивной кавитационной обработке. В большинстве случаев обработка в ДЭВА-С осуществляется за один проход, что упрощает общую технологическую линию.

| Модификация | Краткие характеристики | Типовая конфигурация |

| ДЭВА-Ф.ПРО Включает в себя ГУУМП + ДЭВА-С Готовый мини-завод по получению гуминовых удобрений |

Производительность до 25м3 ОМУ в сутки. Механизированная подача сырья. Сырьё должно быть предварительно измельчено и просеяно до 12мм. Установленная мощность: 42 кВт |

|

| ДЭВА-Ф.МИНИ (ранее ДЭФА-Ф-150) |

Производительность до 2…3 м3 ОМУ в смену. Ручная подача сырья. Сырьё должно быть предварительно измельчено и просеяно до 2мм. Установленная мощность: 8 кВт |

|

| ДЭВА-Ф-200 | Производительность до 5…10 м3 ОМУ в сутки. Ручная или механизированная подача сырья. Сырьё должно быть предварительно измельчено и просеяно до 2мм. Установленная мощность: 15 кВт |

|

| ДЭВА-Ф-250 | Производительность до 15…25 м3 ОМУ в сутки. Механизированная подача сырья. Сырьё должно быть предварительно измельчено и просеяно до 2мм. Установленная мощность: 24 кВт |

|

При необходимости, готовый продукт (ОМУ в форме торфогеля) может быть подвергнут дополнительной обработке для получения гуматов в безбалластной форме.

Конфигурация установок ДЭВА-Ф может быть изменена индивидуально.

Примеры реализованных проектов

Часто задаваемые вопросы

Для младших моделей ДЭВА-Ф сырьё должно быть предварительно просеяно и измельчено до фракции 2мм. Для моделей, оснащённых узлом мокрого помола (ГУУМП), сырьё может содержать камни, ветки и другие включения размером до 12 мм.

Рецептура подготовки удобрений отличается для различного вида сырья. По нашему опыту оптимальное время подготовки составляет соответствует от 5 до 15 циклов обработки в РИА или 1..2 цикла в статическом реакторе.

Возможна подготовка удобрений как с добавками, так и без – это зависит от области применений, состава почвы, выращиваемой культуры и тд.

Стандартной добавкой является калийная щёлочь (KOH). Учитывая наличие обработки в РИА, количество необходимой щёлочи, добавляемой в удобрения, может буть существенно уеньшен по сравнению с обычными мешалками.

Несмотря на стандартную конфигурацию комплекса ДЭВА-Ф, мы готовы изменить конфигурацию в зависимости от Ваших нужд.