Functions

Rotary-Impulse Apparatus (RIA) is a multifunctional equipment which is used for processing mixes liquid&liquid (emulsion), liquid&solid (suspension, slurry) and also liquid&gas. Major functions of RIA are

- homogenization of emulsions and slurries

- processing of oil-based liquid products: homogenization of oil and oil products, improving quality of diesel, gasoil, reducing oil viscosity, reducing paraffin (wax) molecular structures, the impact of water presence in gasoline&diesel (by creating well mixed and homogeneous oil-water mixture

- reagent-free decontamination & disinfection of water (including sewage water), desalination (as a part of DEWA-Deaslination System)

- food industry: mixing pasts&meshes, mixing paints

- liquids activation for further usage

- other

Applications

- food production – for producing&homogenization of pasts, meshes, slurries, etc

- fuel industry – production of homogeneous emulsions from watered fuels, reducing viscosity of oil-based products (e.g. heavy fuel oils, mazut, etc)

- in agreeculture – homogenization & decontamination of bio-humus and humus-based products, production of humus-based fertilaziers

- improving the qulity of network water in heating system by increasing its’ pH level

- removal of hazardous includes from waste water like bacterias and sludge (slime), bringing the quality of wastewater to a level acceptable norms

- many other applications

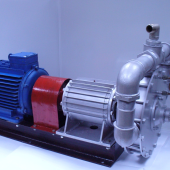

RIA design & modifications

RIA has rotor and stator, noth of them have holes (channels) for liquids. Number of channels depend of RIA-model.

Incoming liquid goes into the central input connector on the front of RIA. Due to centrifugal forces liquid rush to channels in the rotor. Due to permanent rotation channels in rotor and stator periodically coincide what opens the way for liquid to flow outside of stator to the RIA output. Specially designed rotation speed, channels shape in rotor&stator and distance between them – all together form conditions for the creation of cavitation bubbles.

Unlike hydrodynamic cavitators input pressure for RIA is relatively low and does not exceed 4…6bar.

RIA product lines are produced in two major modifications:

- RIA-150, RIA-200, RIA-250

- RIA-150-M, RIA-200-M, RIA-250-M.

Characteristics

Standard RIA characteristics :

|

Parameter |

RIA-150 |

RIA-200 | RIA-250 |

| Rotor Diameter |

150 mm |

200 mm |

250 mm |

| Number of channels in rotor&stator |

18 |

24 |

36 |

| Channels width in rotor&stator |

2 – 3 mm |

2 – 3 mm |

3 mm |

| Capacity, m3/h (on water) |

3 – 5 |

5 – 10 |

25 – 30 |

| Motor |

2,0 – 3,0 kW |

5,0 – 7,5 kW |

15-18,5 kW |

| Rotation speed |

3000 rpm |

3000 rpm |

3000 rpm |

| Power |

380 V |

380 V |

380 V |

| Lenght* Width* Height* |

775 mm 340 mm 345 mm |

970 mm 445 mm 440 mm |

1080 mm 500 mm 630 mm |

| Weight* | 60kg | 110kg | 180kg |

*- might be changed from model to model